Through the use of recyclable materials, energy-efficient production, and waste reduction initiatives, we strive to minimize our environmental footprint.

WE ARE COMMITTED TO ECO FRIENDLY PACKAGING SOLUTIONS

SUSTAINABILITY

At Uniplastindo Interbuana, sustainability is at the core of our operations. We are committed to eco-friendly packaging solutions that reduce environmental impact while maintaining quality and functionality. Through the use of recyclable materials, energy-efficient production, and waste reduction initiatives, we ensure responsible packaging that supports a greener future.

2.011.871 kWh/Year

Solar Panel Output

178.384.019 Ltr/ Year

Megaliters Water

Consumption

Consumption

MAX 1 kWh/kg

Electricity

Consumption

Consumption

Innovative Packaging Design

Light-weight, short-neck, yet durable solutions for minimal environmental

footprint.

Eco-Conscious Production

R-PET (Re-cycle Polyethylene Therepthalate) using 35% - 100% than virgin plastic resin.

EFFICIENCY & STABILITY PROCESS

- Deactivate the Pre-Drying Material in Jug Making Process in Order to Reduce Electrical Cost

- Propose to use PET and Recycled-PET Scraps in Preform Production Process

ELECTRICITY EFFICIENCY

- Installation of Solar Panels at Cikarang, Pandaan and Ciawi Factories

- Using Utility Machines with Latest Technology

- Renew Chillers & Cooling Towers

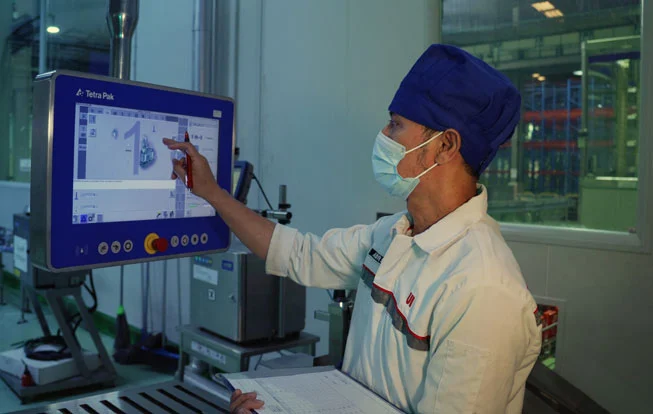

LABOR OPTIMIZATION

- Develop multi-skill Employee by tasks rolling and competency upgrade

- Develop OJT (On The Job Training Programme)

- Develop MT (Management Trainee Programme)

BUSINESS CONTIGENCY PLAN

- 10 Plants (7 in West Java, 1 in West Sumatera, 1 in East Java, 1 in Bali) are available in order to move production to another plant in case there is an issue

- Keep stock for critical machine parts

- Build up stock to another packaging if there is an issue in existing packaging

WATER FOOTPRINT MANAGEMENT

- Utilizing water after the regeneration process at the Water Treatment by filtering and circulate, on cooling & thermal utility process.

- UI has appointed suppliers to process split into scrap. So there is no use of water for this process at UI again

- UI Prefers the dry process rather than the wet process in process split into scrap so that it is expected to reduce water consumption